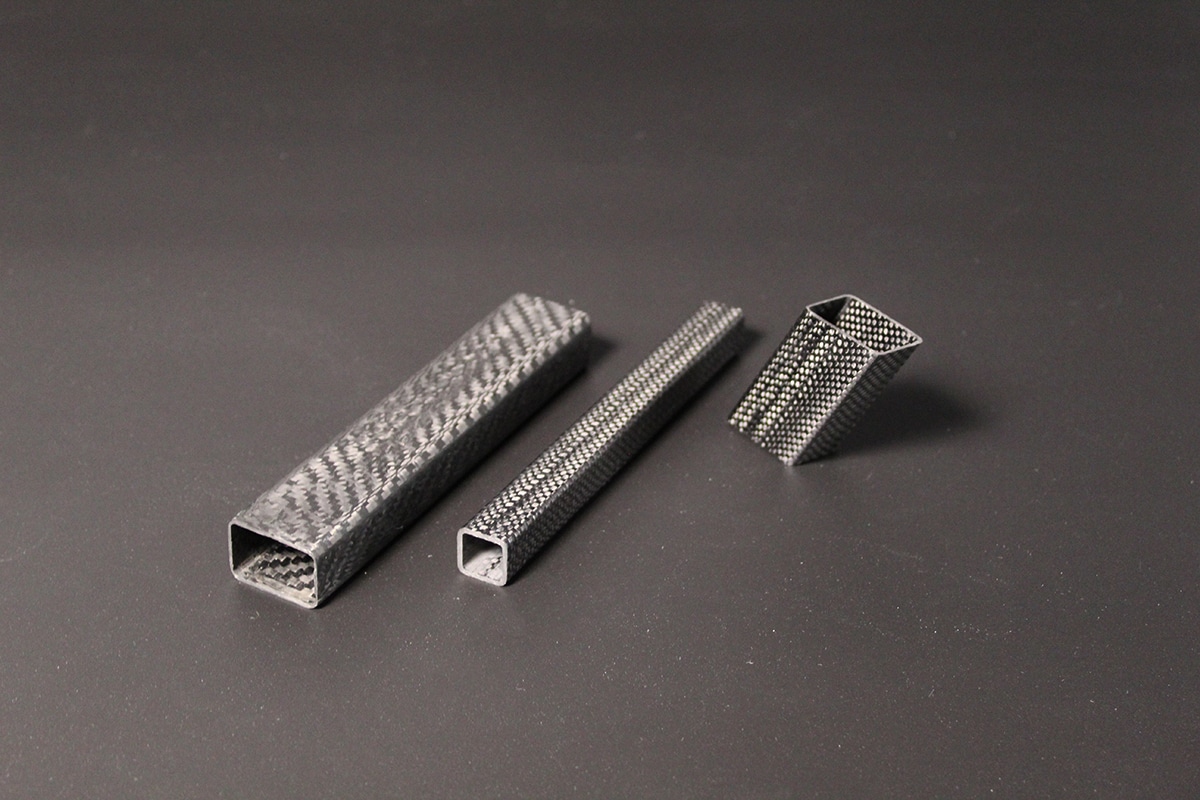

Carbon fiber tubes

GEt USA-Made custom carbon fiber tubes.

-

Made in the USA

-

Full Customization

-

Fast Shipping

Tell us about your project

What makes our tubes better?

INSTANT QUOTE

We have rolled over 1,000 tubes a day since 1962.

The combination of custom machinery and experience allows us to:

-

Produce the highest quality tubes on the market

-

For less

-

Faster than our competition

Capabilities.

Fabrication

We specialize in custom fabrication, offering precision-cut carbon fiber tubes tailored to your exact specifications. Our capabilities include:

CNC milling

CNC turning

Cut to size

Custom finishes

Assembly

Our assembly services streamline your project by expertly combining carbon fiber tubes with precision fittings and components, ensuring a seamless fit. We handle everything from small-scale builds to large production runs, delivering ready-to-use assemblies with efficiency and quality.

Engineering and Design

Our team of composite engineers can help design a solution that fits your needs. Our prototype lab is a micro-manufacturing cell that fast tracks the research and development process. Services include:

Rapid prototyping

Product and material testing

CAD file development

Reach out to learn more.

Why Choose Carbon Fiber Tubes?

Discover why carbon fiber tubes are the preferred choice for engineers, designers, and hobbyists alike—offering unmatched performance and reliability compared to traditional materials.

High Strength-to-Weight Ratio

Carbon fiber tubes offer exceptional strength while being incredibly lightweight, making them ideal for applications where performance and weight savings are critical.

Durability and Corrosion Resistance

Unlike metals, carbon fiber resists corrosion and withstands harsh environments, ensuring long-lasting performance without degradation.

Versatility

Carbon fiber tubes can be customized for a wide range of industries, from aerospace to automotive, providing flexibility for any project.

Superior Stiffness

With high stiffness and rigidity, carbon fiber tubes maintain their shape under stress, outperforming materials like aluminum or steel in many applications.

Aesthetic Appeal

The sleek, modern look of carbon fiber adds a premium aesthetic to any project, enhancing both form and function.

Compare carbon fiber against other materials.

| Material | Strength-to-Weight Ratio | Corrosion Resistance | Weight | Cost | Common Applications |

|---|---|---|---|---|---|

| Carbon Fiber | High | Excellent | Very Light | Higher Cost | Aerospace (drone frames), Automotive (roll cages), Sporting Goods (bike frames) |

| Steel | Moderate | Poor | Heavy | Lower Cost | Construction, Industrial Machinery, Automotive (frames) |

| Aluminum | Moderate | Moderate | Light | Moderate Cost | Aerospace (aircraft parts), Automotive (body panels), Consumer Goods (ladders) |

| PVC | Low | Excellent | Light | Very Low Cost | Plumbing (pipes), Construction (conduits), Signage |

| G10/FR4 | Moderate | Good | Moderate | Moderate Cost | Electrical Insulation (circuit boards), Knife Handles, Marine Applications |

| Basalt | Moderate | Excellent | Moderate | Moderate Cost | Construction (rebar), Automotive (exhaust systems), Marine (hull reinforcement) |

| Kevlar | High | Good | Very Light | Higher Cost | Ballistic Protection (bulletproof vests), Aerospace (panels), Sporting Goods (kayaks) |

| G11/FR5 | Moderate | Good | Moderate | Higher Cost | High-Temperature Electrical Insulation, Aerospace (structural components) |

| XX Paper Phenolic | Low | Moderate | Moderate | Low Cost | Electrical Insulation (terminal boards), Mechanical Parts (gears), Consumer Goods |

| Canvas Phenolic | Moderate | Moderate | Moderate | Moderate Cost | Mechanical Components (bearings), Industrial Applications (pulleys), Marine Parts |

| Linen Phenolic | Moderate | Moderate | Moderate | Moderate Cost | Electrical Insulation (switchboards), Mechanical Parts (washers), Decorative Laminates |

| G3 Phenolic | Moderate | Good | Moderate | Higher Cost | High-Temperature Applications (aerospace fixtures), Electrical Insulation (transformers) |

Explore the benefits of each carbon fiber weave.

3K Twill 2x2

3K Plain Weave

6K

12K